Product Center

- Nano calcium carbonate

- Precipitated light calcium carbonate

- Active Light calcium carbonate

- Superfine Light calcium carbonate

- Heavy calcium carbonate

- Superfine Active Heavy Silver carbonate

- Wet grinding calcium carbonate

- New multifunctional plastic agent

- Baiyanhua

- Needle-like wollastonite

- Superfine Wollastonite Powder

- Dolomite powder

- Calcium Oxide

- Calcium hydroxide

Nanometers are units of length, originally called nanometers, which is 10-9 meters (1 billionth of a meter). Nanoscience and technology, sometimes referred to as nanotechnology, is the study of the properties and applications of materials with structure sizes in the range of 1 to 100 nanometers. From the specific material, people often use fine hair to describe slender things. In fact, people's hair is generally 20-50 microns in diameter, not thin. Individual bacteria are invisible to the naked eye, and the diameter of 5 micrometers measured by a microscope is not very fine. In the extreme, 1 nanometer is roughly equivalent to the diameter of 4 atoms.

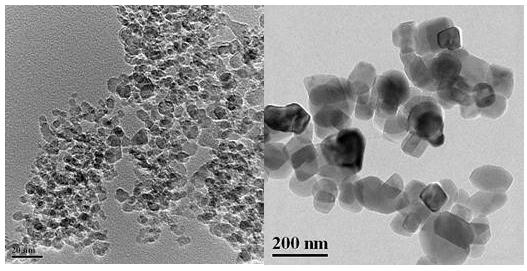

When the material reaches the nanoscale, it is approximately in the range of 1 to 100 nanometers, and the properties of the material will mutate and have special properties. This kind of material, which is different from the original composition of atoms and molecules, and is also different from the macroscopic material, is a nanomaterial.

Nano calcium carbonate, also known as ultrafine calcium carbonate. The standard name is ultrafine calcium carbonate. The most mature industry for nano-calcium carbonate applications is the plastics industry, which is mainly used in high-grade plastic products. PVC plastisol for automotive interior sealing. It can improve the rheology of plastic masterbatch and improve its moldability. As a plastic filler, it has the function of toughening and reinforcing, improving the bending strength and bending elastic modulus of plastics, heat distortion temperature and dimensional stability, and at the same time giving plastics heat retention.

The industrial preparation method of nanometer active calcium carbonate is characterized in that the method comprises the following steps:

In the Ca(OH)2 suspension, the gas containing CO2 is introduced, carbonized to a carbonization rate of 5 to 40%, a crystal regulator is added, carbonization is continued until the pH is 8.0 to 9.0, surface charge and steric adjustment are added The agent continues to be carbonized to a pH of 6 to 7.5 to produce nanoscale cubic calcium carbonate; said crystal form modifier is one of phosphate, sulfate, acetate, citrate, monosaccharide or polysaccharide. And a mixture thereof in an amount of 0.05-3.0% by weight of the slurry; said surface charge and steric hindrance modifier is phosphate, sulfate, chloride, triethanolamine, sodium dodecylbenzenesulfonate. One or more than one; surface charge and steric hindrance modifier added in an amount of CaCO3 0.1-4.0% by weight;

One or two of a fatty acid or water-soluble titanate coupling agent is formulated as an aqueous coating agent; the fatty acid is a C12-C18 fatty acid;

The nano-calcium carbonate slurry is heated to 45-95° C., and then the coating agent is added. The amount of the coating agent is 0.5-3.5% by weight of the calcium carbonate, and the coating treatment time is 0.5-3.5 hours. The material is filtered and dried to obtain nano-active calcium carbonate.

Industrial preparation method of nanometer active calcium carbonate. The method carbonizes a carbon dioxide gas in a suspension of a certain concentration of Ca(OH)2. The nucleation rate of the calcium carbonate crystal nuclei is controlled by the temperature of the Ca(OH)2 suspension and the flow rate of the carbon dioxide gas; after carbonization to form a certain number of crystal nuclei, the control of crystal nuclei formation is converted into crystal growth control. Add crystal form modifier to control the growth rate of each crystal surface, so as to achieve morphology control; continue to carbonize to the end point to add dispersant to adjust the particle surface charge of particles dispersed in cubic calcium carbonate nanoparticles; then disperse the cubic nanocarbonic acid The calcium particles are subjected to liquid phase surface coating treatment. The obtained nano-active calcium carbonate particles are controllable between 25 and 100 nm, and have a cubic shape, a specific surface area of more than 25 m 2 /g, a particle size distribution GSD of 1.57, an oil absorption value of less than 28 g/100 g CaCO 3 , and no agglomeration. The product obtained has excellent performance and can be used as a functional filler in high-grade rubber, plastics, and automotive primers.

Nano-calcium carbonate is used in ink products to exhibit excellent dispersion and transparency and excellent gloss, and excellent ink absorption and high dryness. Nano-calcium carbonate is used as an ink filler in resin inks, with good stability, high gloss, does not affect the drying performance of printing inks. Adaptability and other advantages.

The paper industry is the most promising market for nano-calcium carbonate. At present, nano-calcium carbonate is also mainly used for special paper products such as sanitary napkins for women and diapers for infants. Nano-active calcium carbonate as a papermaking filler has the following advantages: high light-shielding properties, high brightness, whiteness and light-shielding properties of paper products, and high-expansion property, which enables paper mills to use more fillers and drastically reduce raw material costs. Fine and uniform particle size, more even and smooth product; high oil absorption value, can improve the expected firmness of colored paper.

Nano-calcium carbonate is used as a pigment filler in the coating industry. It has the advantages of fineness, uniformity, high whiteness, and good optical properties. Nano-scale ultrafine calcium carbonate has a steric effect. In the paint, it can make the Lid powder with higher density in the formula to suspend and prevent sedimentation. After the paint, the whiteness of the paint film increases, the gloss is high, but the hiding power does not decrease, and it is mainly used for high-end car paint.

One of the main application markets for nano calcium carbonate in the rubber industry. The addition of sodium-calcium-carbonate rubber resulted in higher rubber vulcanizate elongation, tearing performance, compression set, and flexion resistance than the addition of normal calcium carbonate. After adding nano-calcium carbonate treated with resin acid, the tear strength of some of the rubber products increased by more than 4 times. Nano-calcium carbonate can be used as a calcium supplement in the feed industry to increase the calcium content of feed; in cosmetics, due to its purity High, good whiteness, fine particle size, can replace titanium dioxide.